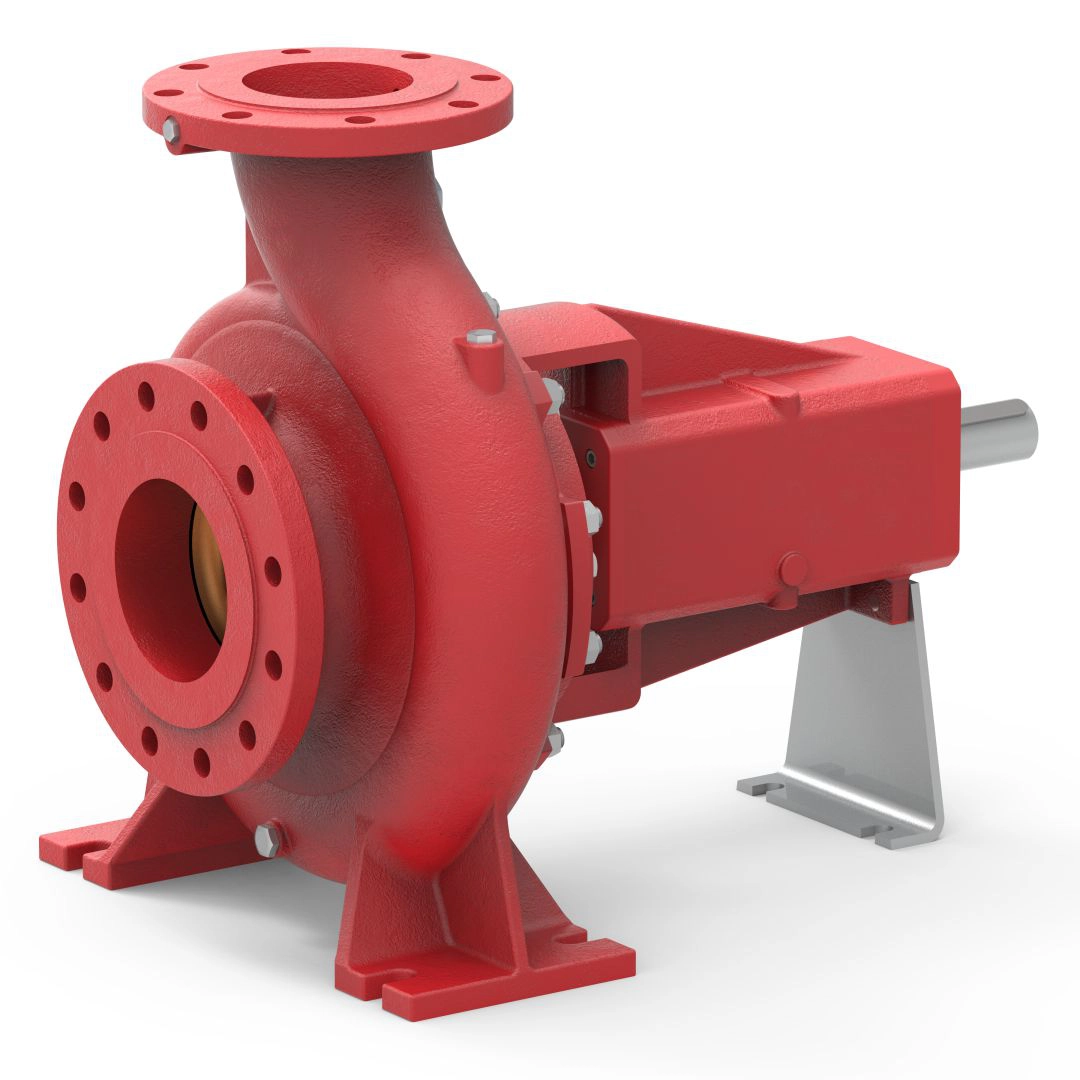

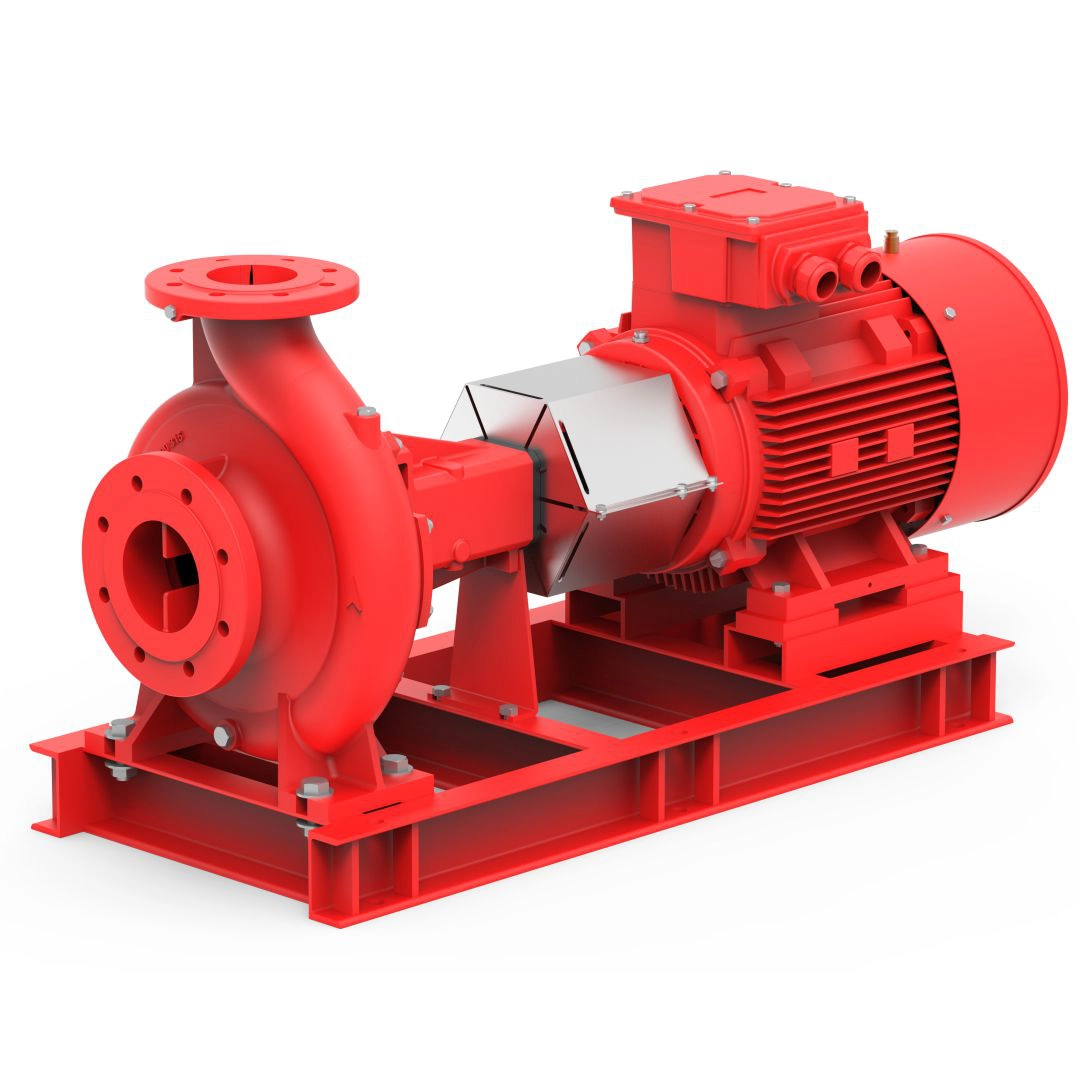

Horizontal End suction fire pump

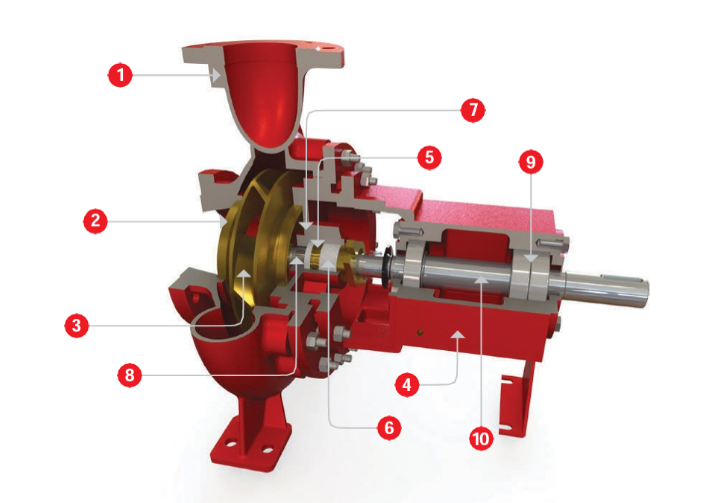

End Suction Fire Pumps are engineered to last long with a precision cast, dynamically balanced, and enclosed impeller that minimizes vibration and maximizes bearing life. Due to its back-pull-out design, the complete bearing assembly including impeller and casing cover can be dismantled without removing the volute casing from the pipe system. This innovative design simplifies maintenance and reduces downtime, ensuring the pump remains operational and efficient over its long service life.

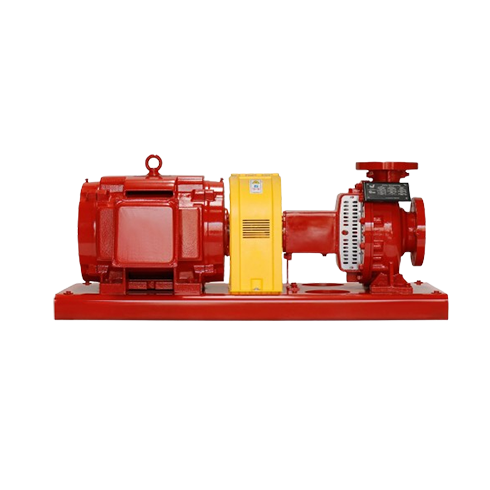

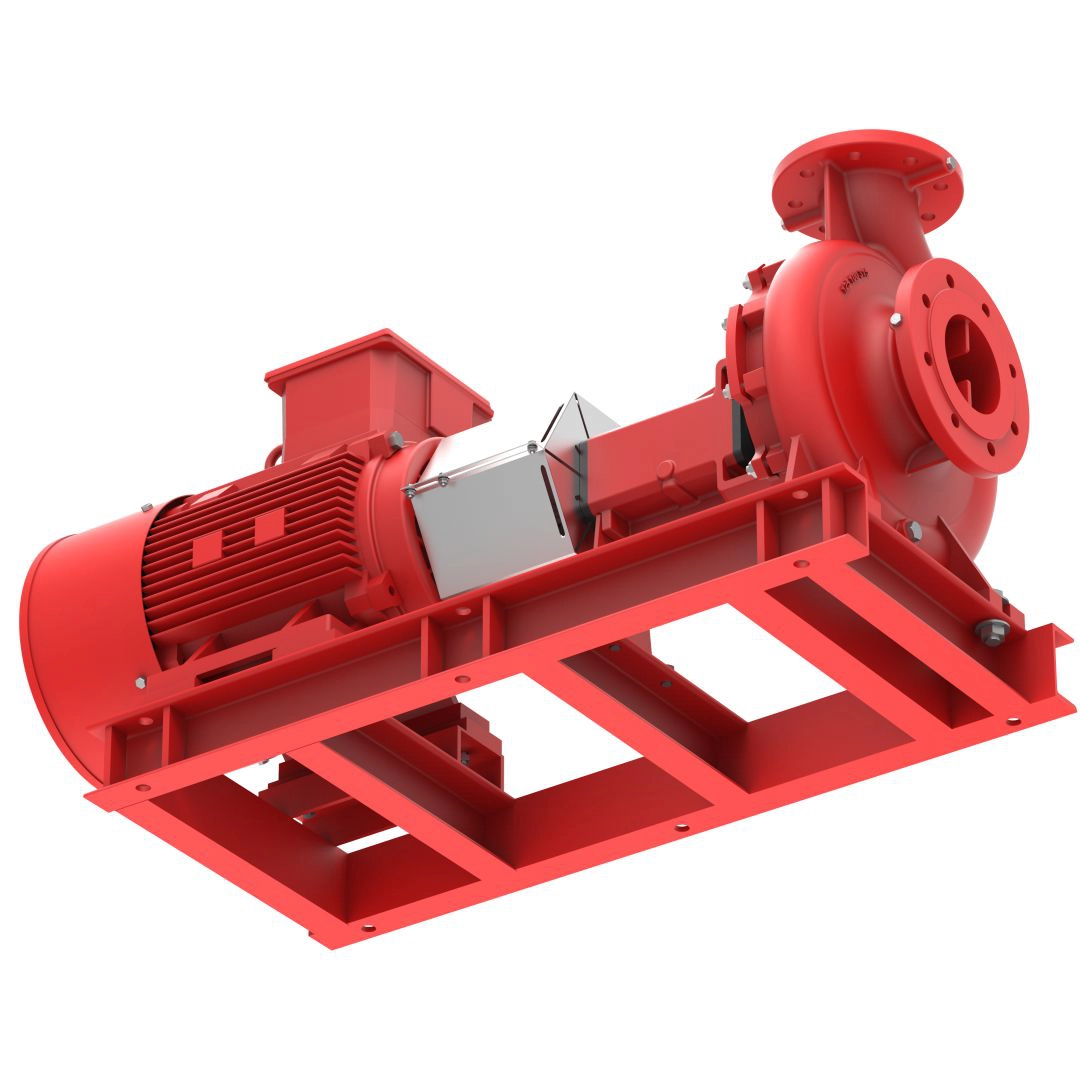

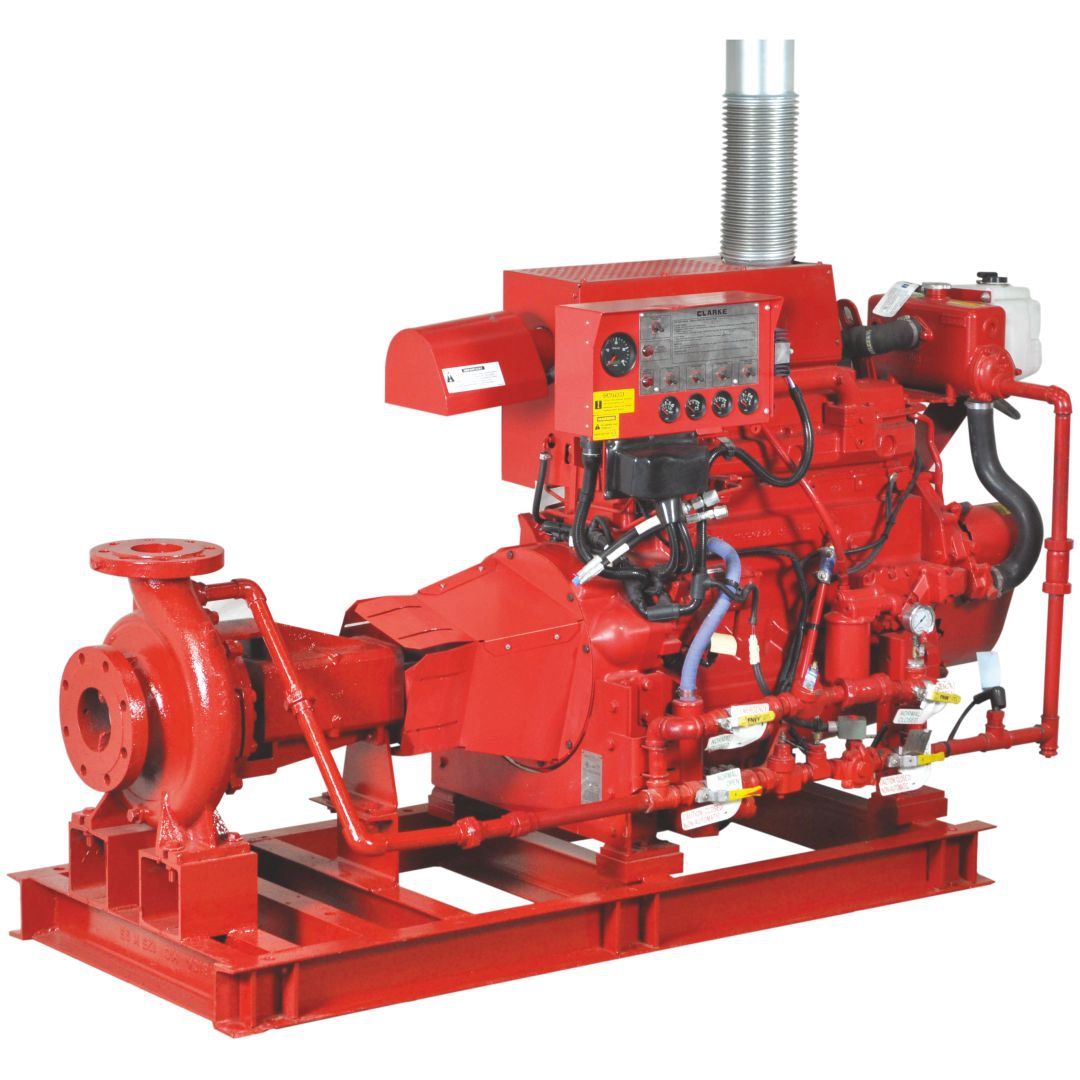

These pumps can be driven by either an electric motor (50Hz / 60Hz) or a diesel engine, offering flexibility to suit various operational requirements. With a full range of options and accessories available, including controllers, jockey pumps, and relief valves, our End Suction Fire Pumps can be configured to meet NFPA compliance, providing reliable performance in fire protection systems. The heavy fabricated steel base is designed to mount both the pump and driver, with a flexible coupling connecting the driver to the pump, ensuring stability and efficient power transfer.

End Suction Fire Pumps are ideal when the water source is above ground, as they provide a positive suction pressure to the pump throughout the performance point. This ensures consistent and reliable water delivery, which is crucial for effective fire suppression. Horizontal End Suction Fire Pumps are available for a wide range of applications and are constructed from various materials to meet specific needs, including corrosion-resistant options for harsh environments.

At Fuller Electromechanical, we are committed to delivering top-tier fire pump solutions. Our End Suction Fire Pumps are built to stringent quality standards and are designed for durability, efficiency, and ease of maintenance. With our expertise in fire protection systems, we provide comprehensive support from selection and installation to ongoing maintenance, ensuring your fire pumps deliver optimal performance and reliability when it matters most.