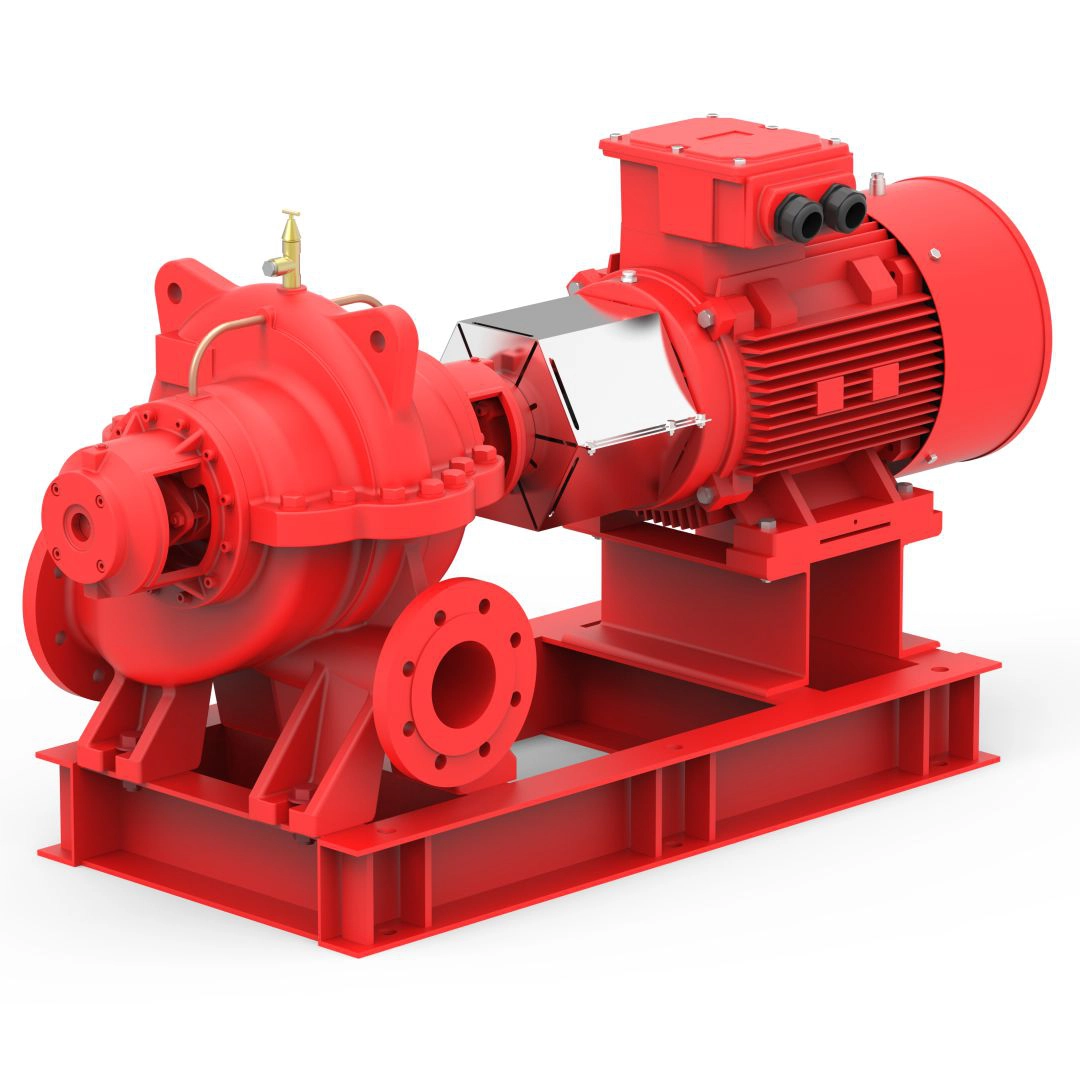

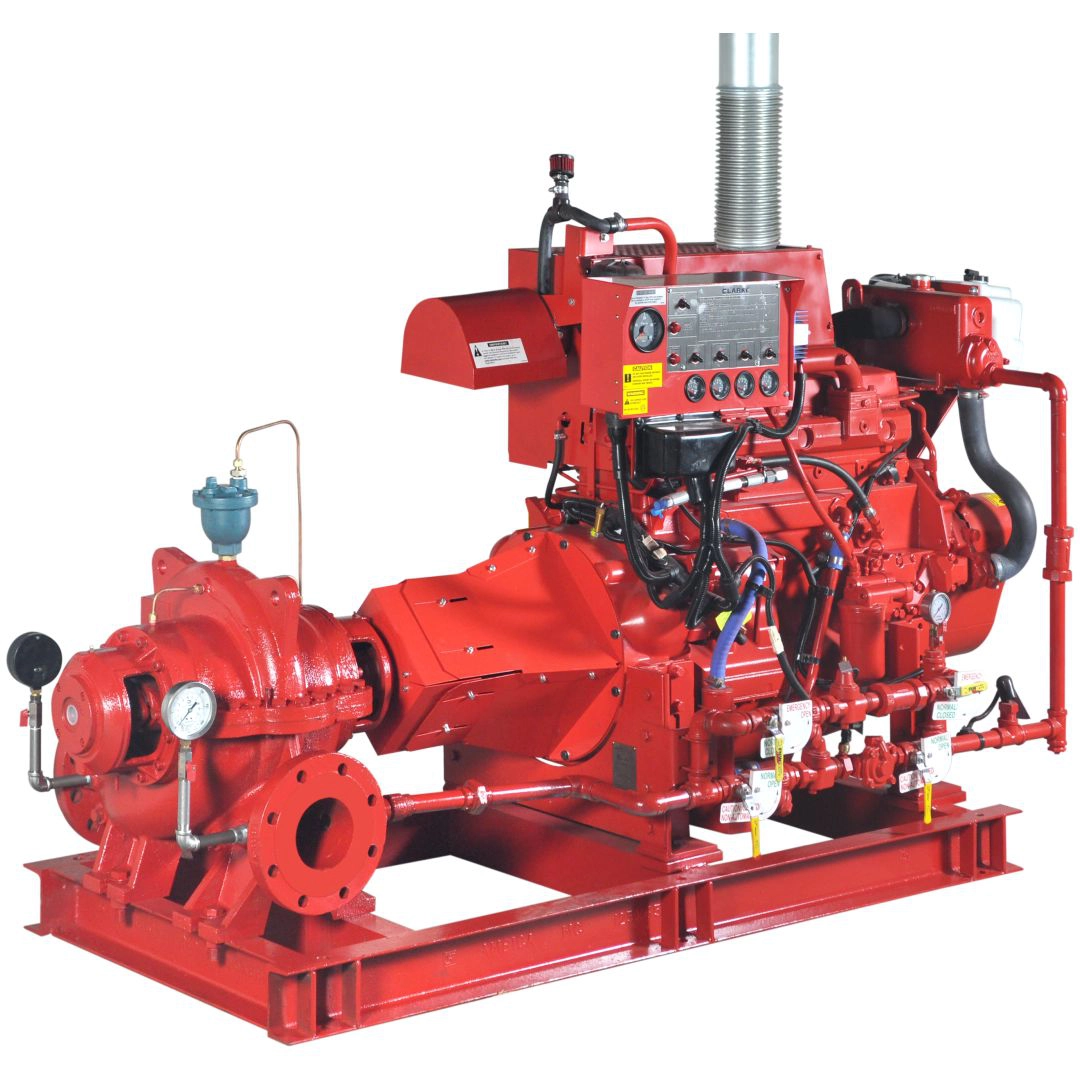

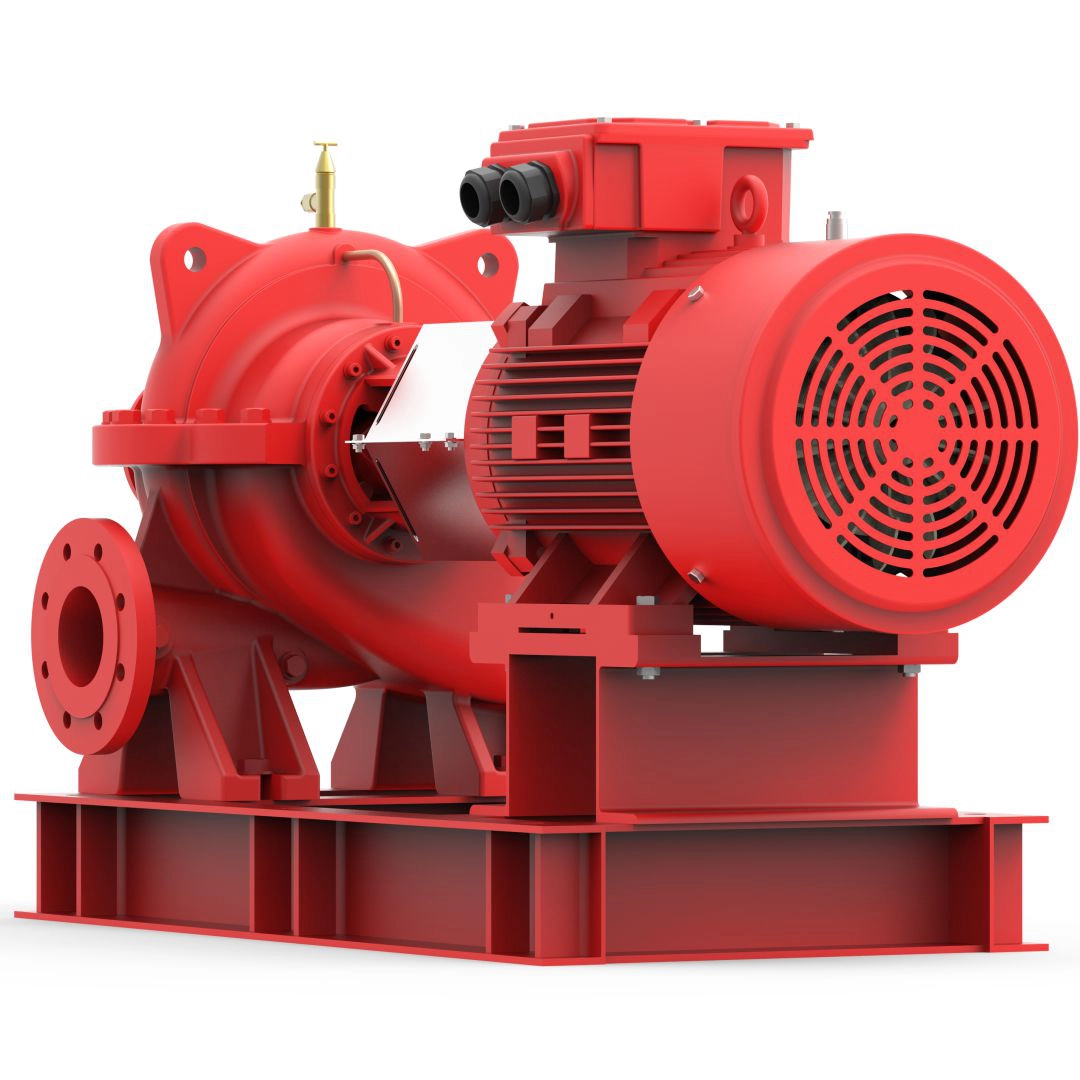

Description

PUMP PERFORMANCE RANGE

-Form 250 GPM to 3000 GPM

-From 58 psi to 174 psi

REFERENCE STANDARDS

- Underwriters Laboratories (UL)–448

- Factory Mutual(FM)–1311 •NFPA20

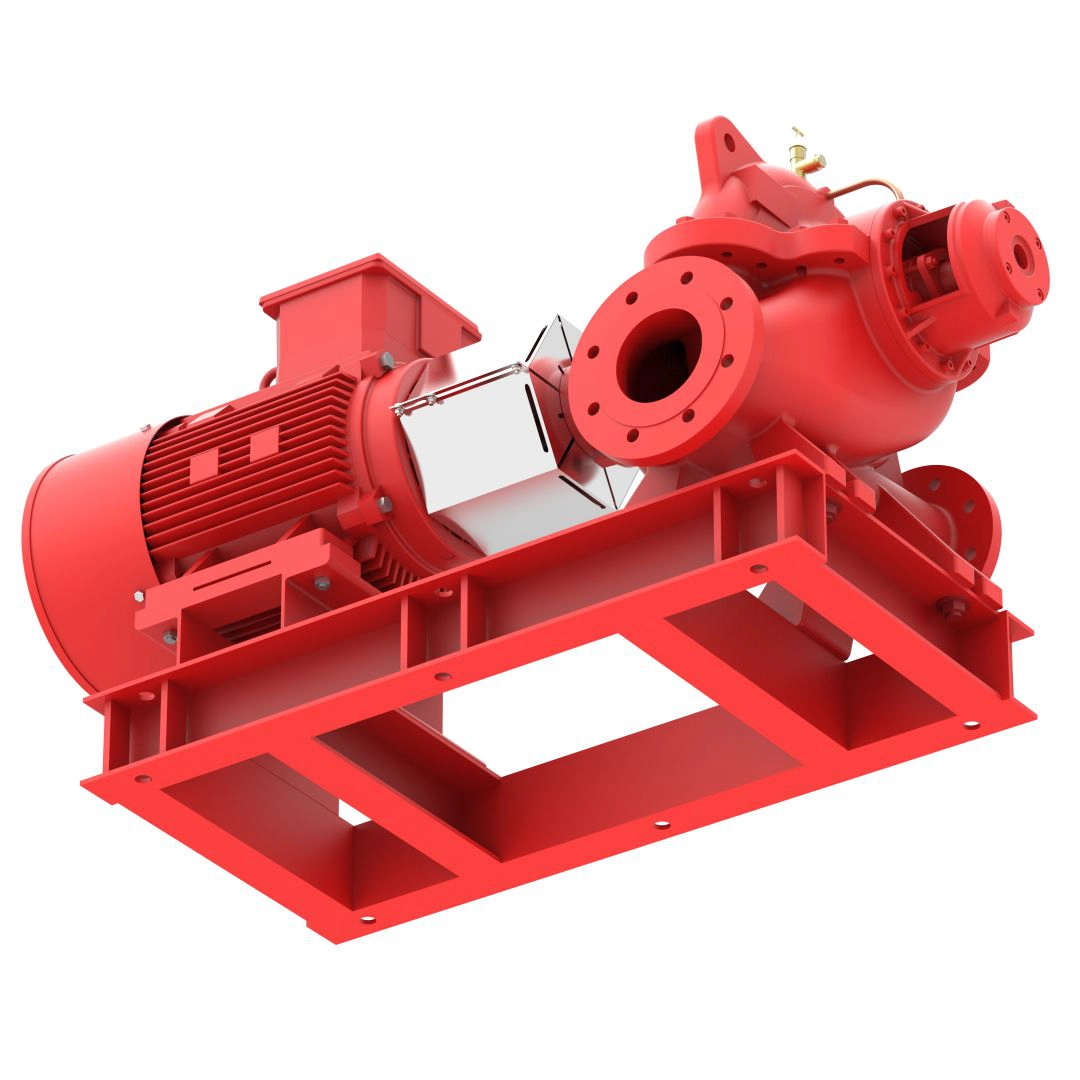

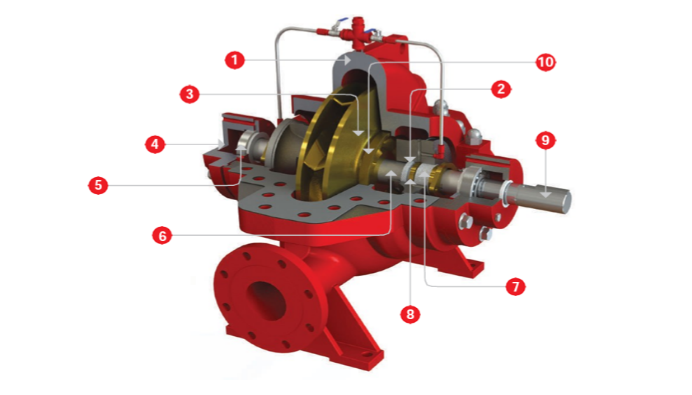

CONSTRUCTION DETAILS:

- PUMP CASING: Rugged heavy-duty, volute type, compact casing split horizontally along the centerline of the shaft. Supporting feet integrally cast with flanged suction and discharge connections located in the lower half casing allows inspection and maintenance without disturbing piping.

- STUFFING BOX: Designed to accommodate a minimum of five packing rings with a lantern ring. Provided with internal passages to allow water for cooling and lubrication.

- IMPELLER: Double suction, fully enclosed, cast in one piece, dynamically balanced before the assembly. Impellers are firmly keyed and locked to the shaft.

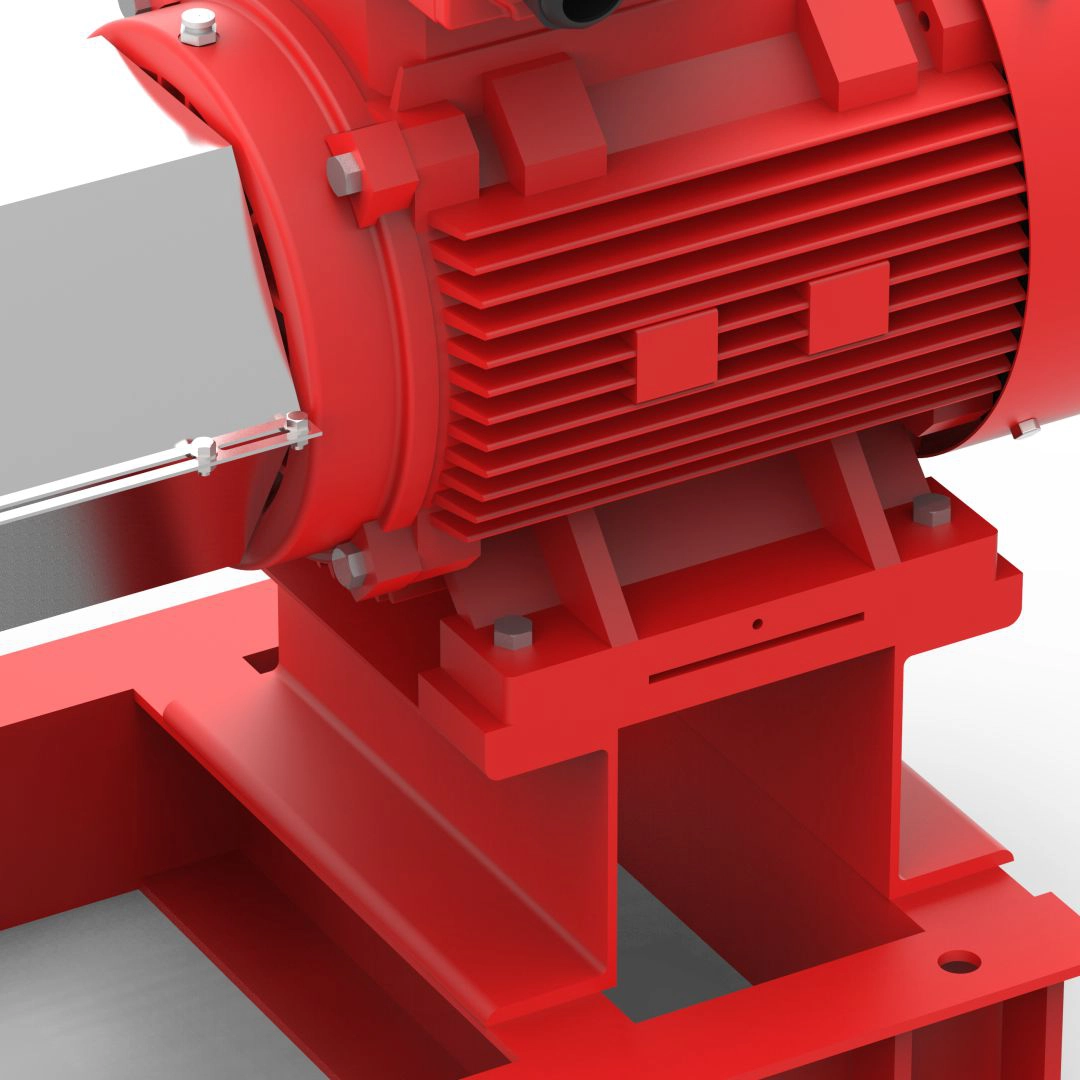

4. BEARING HOUSING: Rigid bearing housings provided with grease inlets and drains and protected by seals to keep contaminants out of bearings. Designed to allow the bearing to be replaced without disturbing any other part of the rotating assembly.

4. BEARING HOUSING: Rigid bearing housings provided with grease inlets and drains and protected by seals to keep contaminants out of bearings. Designed to allow the bearing to be replaced without disturbing any other part of the rotating assembly.

5. BEARING: Grease lubricated steel bearings to maintain the impeller in its central position. Bearings are selected to offer a very high operating life.

6. SHAFT SLEEVE: Centrifugally cast renewable stainless steel shaft sleeves that are accurately positioned, sealed, and locked in place protect the shaft against packing wear, corrosion, and leakage.

7. GLAND PACKING: Graphite packing rings are selected to offer maximum tightness while allowing smooth and friction-free running of the shaft.

8. LANTERN RING: Perforated hollow ring made of corrosion-resistant material designed to allow the flow of cooling water uniformly around the shaft to provide lubrication and cooling.

9. SHAFT: Made of high-strength alloy steel, accurately machined and polished to a smooth surface. Sized with a liberal safety factor to transmit full driver horsepower while offering minimum deflection in full-range operation.

10. CASING WEAR RING: Renewable casing wear ring sized to minimize pressure leakage from discharge toward suction