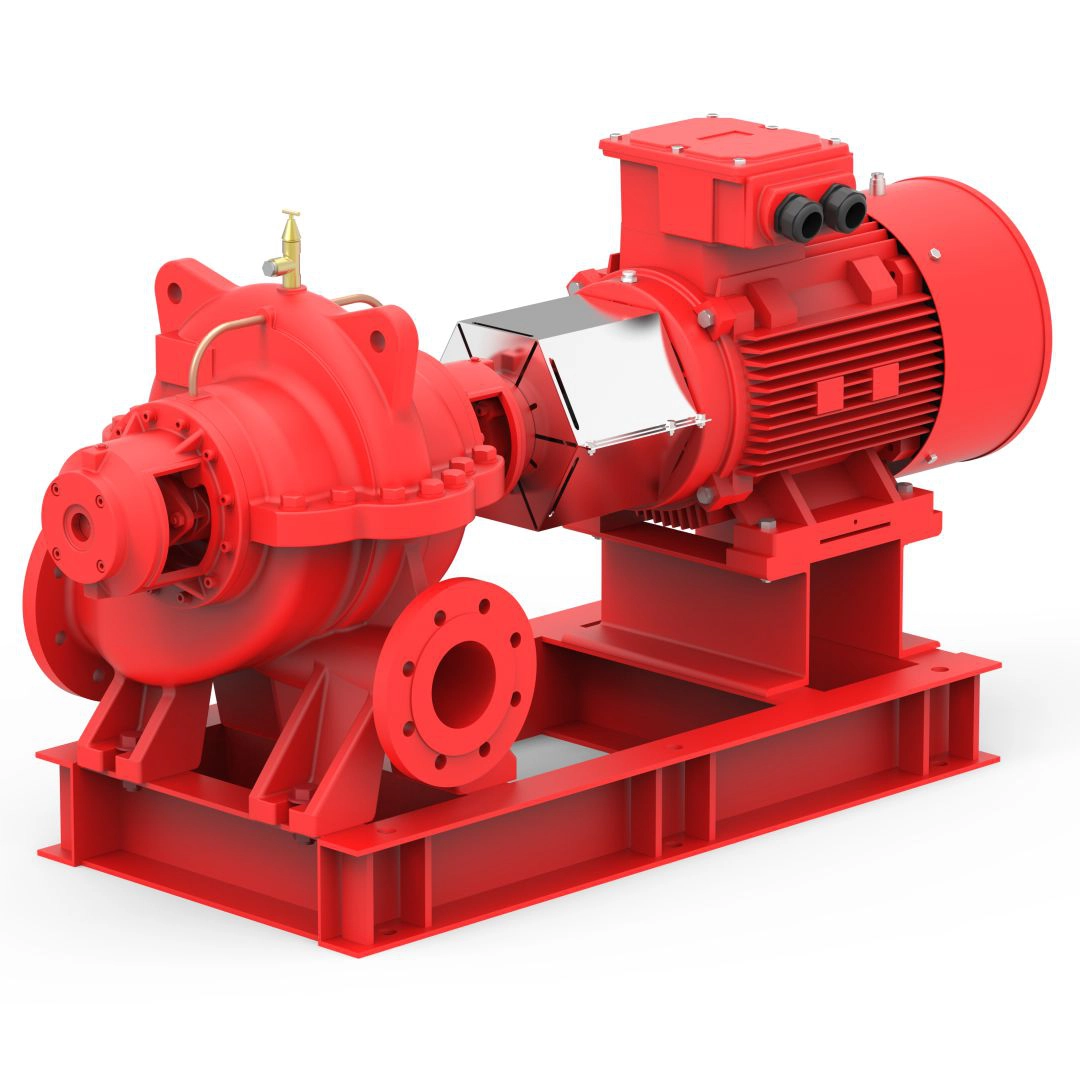

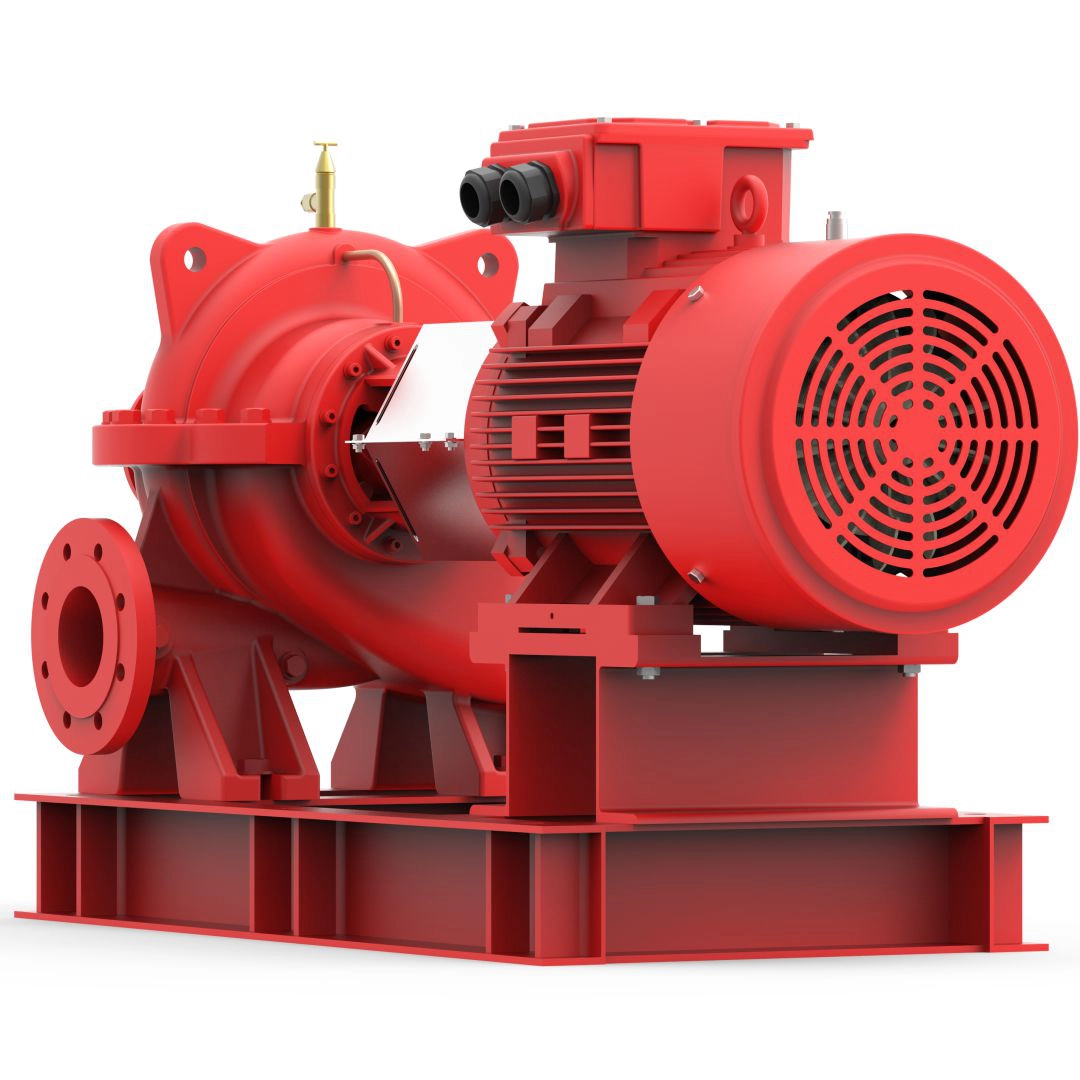

الوصف

نطاق أداء المضخة

نطاق التدفق من 300 جالون في الدقيقة حتى 5000 جالون في الدقيقة

معدلات الضغط من 81 رطل لكل بوصة مربعة حتى 345 رطل لكل بوصة مربعة

المعايير المرجعية

مختبرات التأمين (UL) – 448

فاكتوري ميوتوال (FM) – 1311

NFPA 20

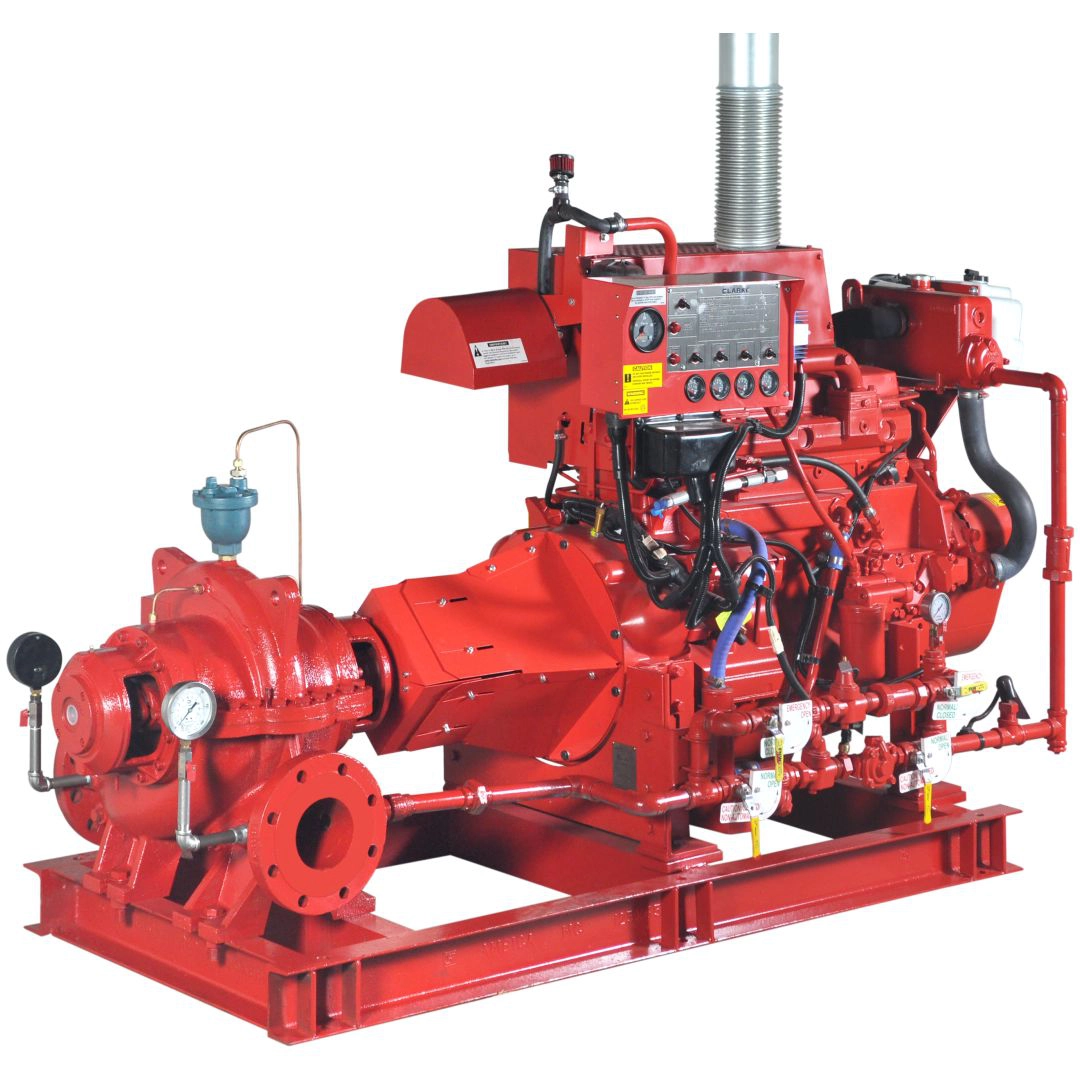

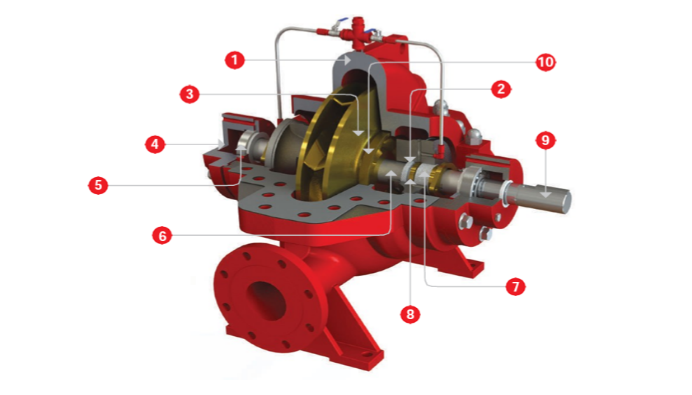

تفاصيل البناء:

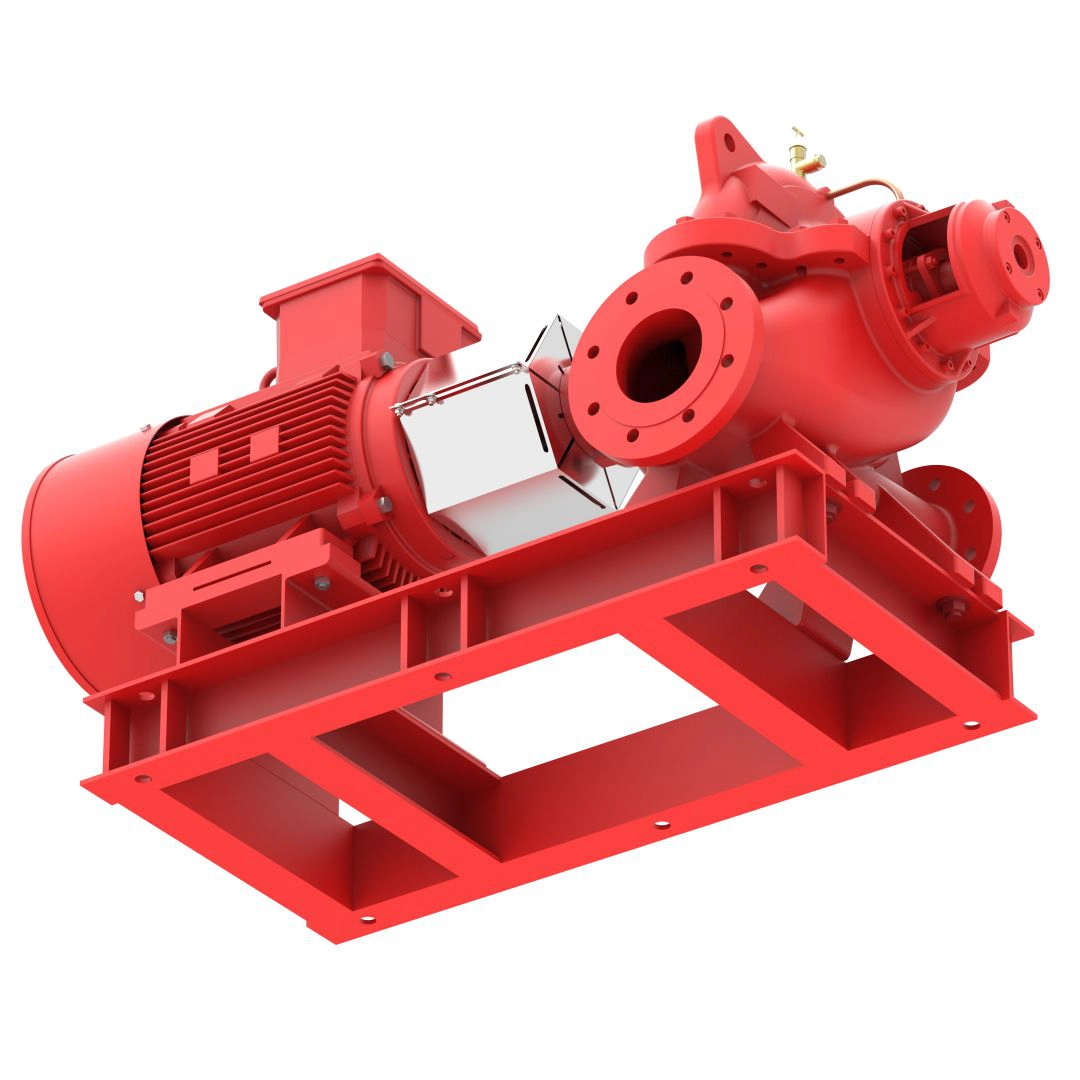

جسم المضخة: مصنوع من نوع قوي وثقيل، نوع الغلاف المدمج، ومقسم أفقيًا على طول خط وسط العمود. يتم دمج أقدام الدعم مع وصلات الشفط والتفريغ المثبتة في النصف السفلي من الغلاف للسماح بالتفتيش والصيانة دون إزعاج الأنابيب.

صندوق الحشو: مصمم لاستيعاب خمس حلقات حشو على الأقل مع حلقة فانوس. مزود بممرات داخلية للسماح بمرور المياه للتبريد والتزييت.

المروحة: مزدوجة الشفط، مغلقة بالكامل، مصبوبة في قطعة واحدة، متوازنة ديناميكيًا قبل التجميع. يتم تثبيت المراوح بإحكام على العمود.

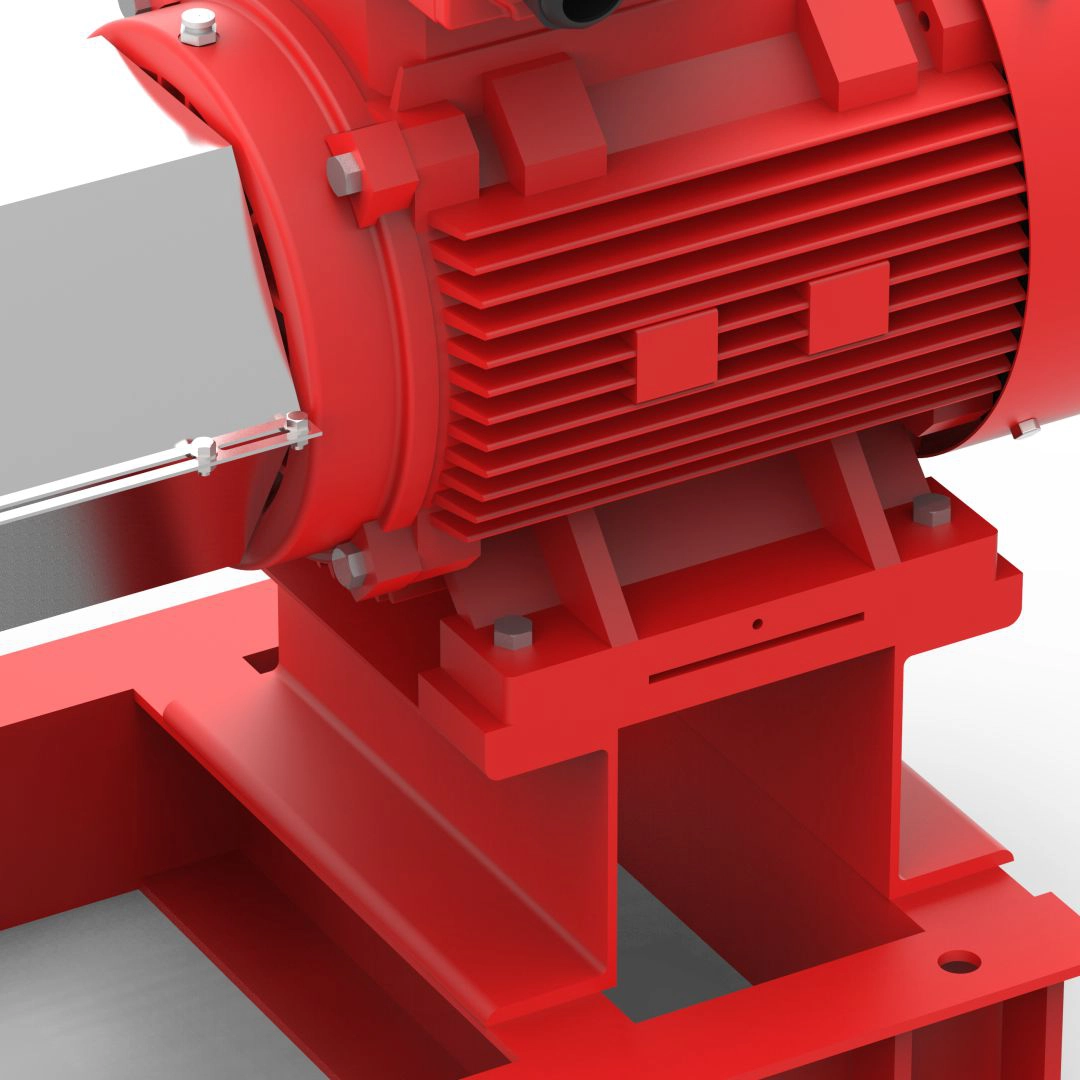

حاوية المحمل: حاويات المحمل الصلبة مزودة بمداخل ومصارف للشحم ومحميّة بأختام لإبعاد الملوثات عن المحامل. مصممة للسماح باستبدال المحمل دون إزعاج أي جزء آخر من مجموعة الدوران.

المحمل: محامل فولاذية مشحمة بالشحم تحافظ على المروحة في موضعها المركزي. يتم اختيار المحامل لتوفير عمر تشغيل طويل جدًا.

غلاف العمود: غلافات العمود المصنوعة من الفولاذ المقاوم للصدأ القابلة للتجديد والتي يتم تحديد موضعها بدقة، مختومة ومثبتة في مكانها لحماية العمود من التآكل، التآكل والتسرب.

حشو الغدة: حلقات حشو من الجرافيت مختارة لتوفير أقصى درجات الإحكام مع السماح بتشغيل سلس وخالي من الاحتكاك للعمود.

حلقة الفانوس: حلقة مجوفة مثقوبة مصنوعة من مادة مقاومة للتآكل مصممة للسماح بتدفق مياه التبريد بالتساوي حول العمود لتوفير التزييت والتبريد.

العمود: مصنوع من فولاذ السبائك عالية القوة، مخرّط بدقة وملمّع إلى سطح ناعم. تم تحديد حجمه بواحد من العوامل الأمان الليبرالية لنقل الطاقة الكاملة للسائق مع تقديم الحد الأدنى من الانحراف في نطاق التشغيل الكامل.

حلقة تآكل الغلاف: حلقة تآكل الغلاف القابلة للتجديد والمصممة لتقليل تسرب الضغط من التفريغ نحو الشفط